TECH TOPICS – Dealing with bolt-in tow eye failures

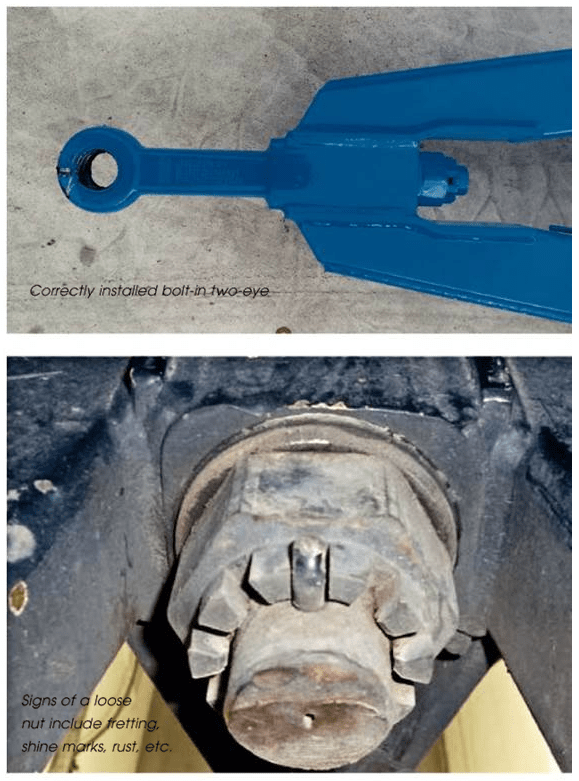

In April a safety alert was issued by the NZ Transport Agency: When a bolt-in tow-eye is not fitted exactly in accordance with the manufacturer’s instructions, the tension and compression forces placed on the tow-eye during normal use can cause the thread pitches to wear and distort. When this occurs the coupling shank or nut will loosen, which in turn allows the nut to be pulled over the thread on the shank. This causes the towing eye to pull out of the drawbar, resulting in the trailer becoming detached.

NZTA stress, “Tightening the nut of a loose bolt-in tow coupling is not acceptable and may increase the potential for earlier catastrophic failure. The complete towing eye and nut must be replaced.” One of the options for overcoming the issue is to outlaw bolt-in tow-eyes. This option may disadvantage operators because of the costs of welding and certifying replacement eyes and the downtime involved. However the safety benefits are significant and if operators follow the NZTA’s recommendation to check the torque of bolt-in units every 15,000km and replace them if the torque is below specifications, the bolt-in system may prove an expensive choice.

Both the NZTA and the Road Transport Forum have previously issued notifications about the security of boltin towing eyes. The NZTA is obviously frustrated that the road transport industry has not addressed the problem and is seriously threatening to ban bolt-in two-eyes. They state in their February 2016 Heavy Vehicle Servicing Information flyer, “We are still seeing incidents of towing eyes coming loose and failing in service. This situation has significant safety risk which is being investigated. As a result the Transport Agency may give consideration to phasing out bolt-in towing eyes completely.”

NZTA RECOMMENDATIONS

What you should do:• Check the security of the towing eye as part of the daily walk around.

• If there is any sign of it being loose (eg. fretting, shine marks, rusting, etc) the tow-eye and nut must be replaced – under no circumstances is it to be tightened.

• When the tow-eye and nut is replaced, the nut must be torqued to the manufacturer‘s recommendation (including a greased thread) and then if necessary taken to the next castellation – in no circumstances backed off.

• Following initial installation the nut should be re-torqued at the lesser of 5000km or as directed by the manufacturer. If it moves it must be re-torqued. Note: this is the only time that re-tightening is permitted.

• One manufacturer recommends checking the tightening torque of the castellated nut every 15,000km. The Transport Agency encourages all operators to follow this recommendation.

If the nut is found to be loose the complete towing eye and nut must be replaced.

Read more

Wide load follows

0 Comments9 Minutes

Lined up and in Balance

0 Comments8 Minutes

UNDERSTANDING YOUR BATTERY

0 Comments6 Minutes