The Magpie. A tenacious, stealthy, skilful, opinionated, and witty creature with innate confidence and a keen eye for shiny things. Born not with tolerance for fools, or that which falls short of a Bulldog‘s tenacity.

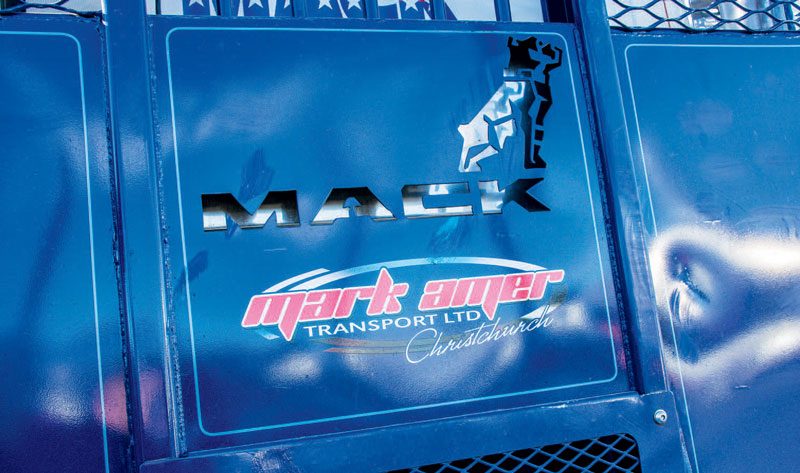

If you‘re a Kiwi truck buff in the second decade of the twenty-first century and the surname Amer induces a blank look, then you‘ve been in a coma. Hailing from Canterbury‘s biggest village, the Amers have a trucking lineage that stretches back generations; diesel flows through their veins like sap through the fibre of a well pruned pine. In recent times their identity has spread to the nation‘s far-flung corners via the Magpie‘s Truck Photos Facebook page, founded by brothers David (‘Spike‘) and Mark (a.k.a. ‘Magpie‘). As is common for the vocation, their views on things are fearless and rarely difficult to interpret. These people are hard, devoted, uncompromising, trucking types.

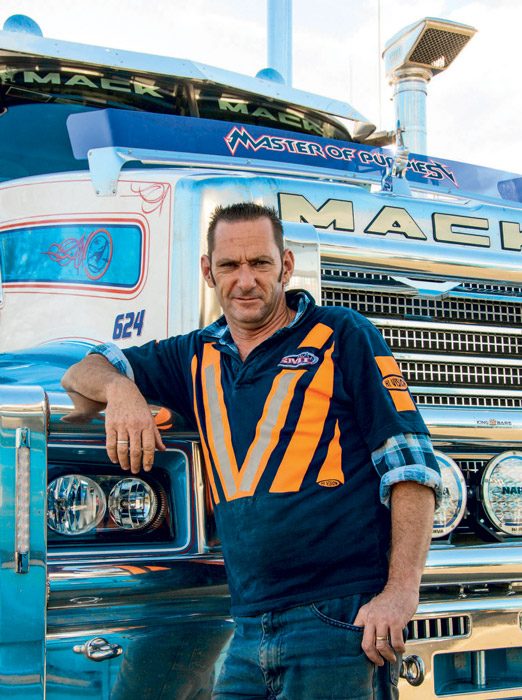

Magpie is the youngest of four. An owner-driver for 14 years with the immaculate Christchurch trucking operation that is Steve Murphy Ltd (SML), he‘s a Mack man and recently took delivery of his second Mack Trident, following a near faultless 800,000km run from his first. Sitting in the SML Kaiapoi yard the ‘Master of Puppies‘ sparkled in sync with its surroundings on a frosty Canterbury morning; a scene that signalled the beginning of a three-day adventure full of robust and insightful conversation in sublime winter conditions.

This truck and trailer is no celebration of skin-deep beauty; the breeding in this canine carrier of commodity goes all the way to the soul of the metaphor encompassed in one of the globe‘s most recognisable emblems. Climbing into the cab, the first thing that‘s apparent is that this mid-winter log truck hasn‘t just been cleaned for the event. This is the tool of a proud craftsman who takes his business and profession as seriously as it comes.

Magpie leaps in, releases the park brake, moves the stick into gear, slips the clutch, and we‘re off. Yes, that‘s right, we‘re in a manual! It really is going to be a great few days. There‘s no question we live in an increasingly AMT world and that trend is only going to curve upward with the advent of alternative power, and the march of Euro 6. Sure, the day will come when people will look back condescendingly and wonder how we of the old school ‘ever put up with that‘, while we sit in our easy chairs and reminisce on a time when a driver actually ‘knew‘ his or her machine. Having said that, it‘s still not hard to find plenty of manual shifters in logging and other niche areas, or in the hands of those with ‘Sinatra‘s Syndrome‘: preferring to ‘do it myyy wayyyyyy‘.

We‘re on the road now and the infrequency with which gears are changed impacts the senses straight away, as does the innate interpretation of topography and risk factors. The processor controlling this transmission is several million years into its development and this particular example has been customised for the task since birth. The spark and wire jobbies, by comparison, are a mere decade or three down their evolutionary track, and it shows.

We‘re on our way north to a log skid at Hanmer for a load into a local Christchurch sawmill, and then back for another into town from the Ashley Forest out to the west. “I come up here a lot,” said Magpie as the Trident rolled through Amberley en route. “There‘s a lot of flat running down here, the gnarliest forest would be Okuku, a bit further into the base of the Alps.” The topography flanking the Alps means climbing empty up to a skid, and then a tricky loaded descent is often the go, but the Hanmer skid was a doddle. Two hundred-odd metres off the council road, we were in and out in about 40 minutes. The Ashley Forest load later in the arvo was plucked off the top of a hill and then we rejoiced in the classic log truck descent with engine brake ablaze and dust galore. It may not have had the speed of a classic Neil Allport or Kim Austin Ashley Forest lash, but it lacked nothing in terms of theatre. Rolling down off the ridge we met the main council road and headed for the Garden City.

Photo: Loading in 2019 is a ‘stay in your cab‘ affair. Phone App shows the scale read-out. Handy as when you‘re in the loader first thing in the morning.

A breed apart

When it came time to replace his previous truck, Magpie was asked to consider a move from his 6×4 and 4-axle configuration to a 9-axle HPMV. “I knew it was coming but the more I looked the less I was able to justify it,” he said. “There‘s so much you have to take into consideration and they‘re not a one size fits all thing, you know? Sure, carting back and forth from, say, Dalethorp [a processing skid in West Canterbury] into the wharf or something, no problem … but my work can take you to half a dozen different places a day; main roads, council roads, big bridges, old bridges. No, they don‘t tick enough boxes. You have to think about RUC, outlay, running cost, manoeuvrability. They are not the be all and end all, believe me.

“Thankfully Steve and Chris [Murphy] are great blokes to work for, I wouldn‘t have been here for sixteen and a half years if they weren‘t, and they let me make the final decision. The one I thought best suited my business. It‘s a shit tonne of money to outlay and this combination goes anywhere. I don‘t even run it on a higher route-specific RUC. It just goes anywhere.”

Photo: Down down down from the loading skid in the Ashley Forest.

As such it was another 6×4 and 4-axle that got the stamp of approval. But that was just the start. Living up to his nickname, the truck is much more than it appears on face value; it‘s a collection of things put together just how he wanted it … and some serious shine to boot. “People say, ‘Oh they‘re all just platforms now‘, but, believe me, you can custom build a Mack far more than people think, and more than other brands touting ‘custom-built‘.” The first thing Magpie wanted was a hefty chassis, and so the truck has the 11mm-thick rails found on bigger brutes in rugged applications.

“I‘m not an out and out payload chaser. It‘s all very well building them light to carry more but, with cartage rates where they are, it takes a hell of a lot of payload to compensate a big engineering fix. And I wanted something that wasn‘t going to move around with a load on.” Likewise bolster positioning was regionally customised to garner the best blend of position, handling, and traction. “We don‘t have the bigger loaders down here, things like Wagners and that, and we cart lots of 3.7 and 4.0m wood; so I‘ve positioned them precisely with a 2.6m spread. Builders say ‘Are you sure you want them there?‘ ‘Yes, I‘m sure‘. That‘s what I like about Kraft and one of the reasons I keep going back. They‘ll ask, and that‘s fine, but they don‘t argue.” The diff and cross locks on the truck are independently activated, meaning Magpie can lock up one or both axles. “A couple of people have said ‘Shit that‘s a good idea, I never thought of doing that‘.

Photo: Drivers loading their first round is par for the course in the big land.

“You have to be able to steer the bloody thing in the shit. I‘ve not gone for super-singles on the front steer tyres either. I‘ve had previous experience with them on a 6-wheeler and they just understeer too much in this work on these roads.” The trailer is a Magpie special, too. Again, Kraft got the nod because of the willingness to do what he wanted and because, in five years of operation, the previous trolley never saw the business end of a welding rod in order to repair a crack. “I bought a secondhand truck years ago that had Kraft gear and it was light and reliable. They also built my drop chassis design on this and the previous one, others wouldn‘t. “I went for Hendrickson INTRAAX disc brakes on advice, the same as last time. When I sold that trailer it still had six of the original callipers on it with one round of rotor replacements. People told me originally to shy away from discs and maybe early on they were troublesome. I‘ve not found that at all.”

Photo: An impressive sight watching the truck being unloaded…and deceptively quick.

…and now for shiny things

Magpie‘s not a career trucker, he‘s a lifetime trucker. As such, he‘s particular about what he likes and how a truck should look. There‘s no disputing the latest edition is a beautifully balanced combination; few set-ups can surpass the aesthetic appeal of a classic 6-wheeler and 4-axle trailer. But the Mark Amer Transport Trident gets it right on so many other levels.

Of course, starting with a beautiful base machine helps immeasurably, and the Axle Forward (AF in the nomenclature) front axle Mack Trident most certainly is that. The balance is enhanced by the clever placement of diesel and DEF tanks, exhaust gear, and toolboxes. The truck looks the same from either side. Add some Chris Stanley chrome magic to Mack‘s list of available decorations: a pair of straight cut stacks, round air horns, retro bullet lights and a King Bars four-post Warrego bull bar, and you‘re in business. On the subject of the bull bar, Magpie didn‘t want the classic Aussie cow-catcher underneath – rather, he went for a flat plate that he could mount lights on. Rounding out the visual symphony are SuperChrome rims, a row of Narva spotlights forward, custom light-bars and bumpers aft, plus an illuminated Mack logo stencilled into the steel headboard.

The final product is a superb looking, incredibly practical and easy to use tool of trade. A 45-tonne GCM runner, it‘s able to cart 29 tonne absolutely anywhere save bespoke and irritating rural bridge limits.

‘You better work!‘

A song lyric but oh so appropriate. The reason Magpie is so pedantic about the specification, layout, and position of things on his gear is the overarching requirement for productivity. The truck must be an extension of him like a competitive chopper‘s prized axe. Bling is great, and touches on ‘who‘ he is, but it must be out of the way and on no account hinder efficiency. He‘s one of those blokes who is an illusion when working around the machine – methodical and measured in appearance, yet impossible to keep up with when alongside. He‘d be dust in the distance when most were chaining their fifth of nine chains. The set-up of the gear contributes volumes to that ability.

Day two was ripper with one out of the Dalethorpe skid site back to the Daiken board plant in Sefton, and then a load of sawlogs from the Hanmer site again, this time up to Kaikoura via the Inland road.

One huge difference in log trucking once the ditch is breached southward is first round loading. Come to the mainland to blat around the bush and you‘d better know how to operate a wheel loader and/or a grapple, as it‘s the norm for the truck drivers to put their own first loads on. “It‘s not like it used to be, it‘s lessening over time, and drivers are trained and signed off now. I started by having a go while the gangs had smoko, and watching good operators. You learn a lot by shutting your trap and watching a good operator,” said Magpie.

With a wheelbase of 6495mm the turning circle of the Amer hound is out beyond 20m. Ironically, it‘s not a huge thing in logging, as jiggling and backing into position are all part of life‘s joyous moments. If you have to do a five-point turn anyway, a seven‘s not such a big deal…most times. The random pulp heading to the Daiken mill was no poster load, but Magpie had it on in no time. It‘s a short, sharp drop off the skid back out onto a narrow bitumen council road that sees more than 40 log truck movements a day. In true log truck fashion, everyone knows where the others are via the bush radio.

It would appear also the roading engineers from these parts had been away from school back in the day when camber was covered. So many of the long straights end in a flat corner, so you want to be comfortable in the knowledge that you‘re in a sure-footed steed.

Fine tuning of the front tyre pressures has got the steering right where he wants it. “The Macks steer really well. I had an SAR Kenworth and you needed both hands on the wheel of that on these roads, but this thing holds its line no issues at all. “See that little oscillation side-to-side the bonnet‘s doing?” he said. “This one‘s done that from new, the old truck never did. Doesn‘t affect the handling or anything. I‘m wondering if it‘s the bull-bar. After all, it‘s 250kg hanging off the front a metre ahead of the front axle. I might put bigger shocks on it and see what that does.”

We were most interested as it was the same movement we picked up in the AROCS last month and commented on. Gary Phipps has weight right up front also in the form of a car parked on his head. That explains it, we thought.

Inland

At the board mill, the huge gantry crane (made right here in New Zealand by Brightwater Engineering) had the load off deceptively quickly. As the frost took hold we were away to Hanmer again. The inland road from Hanmer to Kaikoura is a great test of man and machine. Like so many of our more interesting bitumen arteries the road chases river valleys, catchments, and ridgelines. It was the first corridor opened into Kaikoura following the 2016 earthquake. The occasional stock truck and a Norman‘s Transport Volvo were the only heavy gear encountered. You‘re only in here if you need to be in all reality. “Whether you take this or the Leader it doesn‘t really matter, six of one,” says Magpie. “We‘ll come back via the Leader Road for the on-cart home. Bert‘s [SML operations supervisor, Jason Lyon] jacked us up a load out of Hanmer back home. He‘s a bloody great dispatcher. Been around it so long and knows it inside out.” There was no ‘In the tricky bits I put it in manual‘ here. It‘s been in manual since the day it rolled off the line at Wacol in Brisbane. Magpie had the Bulldog on a firm leash and his ‘run‘, ‘heel‘, ‘sit‘, ‘fetch‘, instructions were issued meticulously via the gear lever and three pedals.

“There‘s no long grinds in here, just short sharp bastards, one after the other.” No shoulders on the road at all and narrow lanes, it‘s these times the firmer feel of a US-style set-up comes into its own. They‘re trucks that communicate what they‘re doing and the stresses they‘re under via the seat of the pants, usually by way of a front pivot and rear airbag/shock cab mount set-up – as was the case here. The interaction is amplified when ‘slim‘ is poking up through the floor requiring gears to be changed. It‘s amazing what a couple of pivots and a gear lever can tell you. Having a physical connection to the chassis makes it easy to interpret exactly where the truck is and how ‘ol‘ mate‘ up front on the hood is coping. It‘s hard to believe the parent of this machine make some of the most insular and automated driving environments on the planet.

As we chatted, we wondered if the over-insular so-called state-of-the-art cabs have contributed to the increased crash rate of big trucks in recent years. In many, there‘s no physical connection between driver and his machine, just air, wires, and sensors. And that‘s a good thing? We‘re reminded of a fantastic comment made by Shane McFarlane in the Satherley T900: “When I was a kid we piled into the HQ and if it was cold or frosty outside you knew it. The old man would be wiping condensation off the windscreen. You drove accordingly. If it‘s this cold inside, then it must be bloody awful out. Now the inside is a perfect twenty-two degrees and the windows are crystal clear. You don‘t know it‘s icy or greasy.”

Back to ‘ol‘ mate‘ up front, in this instance silver on account of the truck not having a full proprietary driveline. Under the bonnet is the 12.8-litre, 6-cylinder, overhead cam MP8 engine. It‘s Euro 5 via SCR with with Mack V-MAC IV engine management system. The power peak is 400kW (535hp) at 1450rpm, which hangs around until 1900rpm. Torque hits its 2603Nm (1920lb/ft) straps at 1050rpm and doesn‘t throw power the performance bone until 1450rpm … making that particular number a handy one indeed. Backing up the engine, and the first reason for the silver tinge on the hood is an Eaton Fuller RTLO22918B 18-speed transmission that feeds into silver dog reasons two and three, Meritor RT46-160GP axles at 4.1:1. Up front, Mack‘s FXL 14.6 axle, at 6600kg capacity, rides on 1397mm heavy-duty parabolic springs and shock absorbers, and rearward the Meritors sit on Mack AP460 air suspension rated at 20,900kg, which is in fact a Hendrickson PRIMAAX. “I like the PRIMAAX,” said Magpie. “Really good on traction and more importantly very stable on the road.” The truck‘s on drum brakes with ABS and auto slack adjusters and the trailer is on disc with EBS and ABS. Because there‘s no mDRIVE there‘s no Grade Gripper (hill start assist), and there‘s no additional ‘safety‘ trickery or electronic stability.

“Just old school. Load it, go, and try not to tip it over.” He‘s a forthright fellow isn‘t he? The Inland road provided the perfect stage for demonstrating the engine‘s stickability with a growly note to the motor when the load was felt, but the dog wouldn‘t let go. On a particularly nasty set of switchbacks, just north of the rural hamlet of Waiau, the Mack saw 1200rpm and 28km/h in fourth low (eighth if you‘re that way inclined) and that was without a run-up courtesy of an inconvenient bridge at the base. Nothing else saw the truck out of the high range, or sub 30km/h. Kicking it off 1400-odd rpm takes some doing. Not surprising when you think the peak torque is only 176Nm (130/b/ft) off the MP10. Downhill the PowerLeash engine brake will deliver 315kW (495hp) worth of holdback at 2100rpm. Its contribution was clearly evident. Mack make much of the MP8‘s frugal appetite, and, considering the work profile, the 2.2kpl Magpie‘s seen out of the box with this truck is more than acceptable. “The C16 I had in one Kenworth did 1.6, the Cummins ISX EGR disaster 1.65, the last Mack 2.1kpl. This one is 2.2. It makes a hell of a difference to the bottom line at the end of the month.”

Most people see log trucks as 50% loaders but that‘s often not the case. Magpie said he would be north of 65%, and offhighway motoring is the nemesis of fuel consumption. “All you have to do is muck around trying to get out of one shitty skid and that‘s any fuel economy dreams gone for the day.” Running out to the coast and up the main drag a tad to Kaikoura, Magpie unloads at Prime Pine Ltd. Their yard is right on State Highway 1 so access is easy, although it‘s tight and can be boggy. Not today. Trailer up, it‘s back to Hanmer via the Kaikoura Coast and Leader Road.

Summary

Often the road test is about a firm that bought a truck and how that truck is going. Rarely now is it about an individual craftsman who‘s bought a new tool of trade. The only one he has that can turn a dollar. One that he‘s fashioned, one that has to be right if he‘s to make ends meet. Magpie Amer didn‘t replace his existing Mack Trident and Kraft trailer on the back of a cheap deal – he bought it because the people who sold it listened to what he needed and built what he wanted.

After 800,000km of trouble-free operation in the previous rig, he knows what‘s required in terms of outlay and effort in order to have a bit left over at the end of the month. He needs gear that‘s stubborn, tenacious, frugal, that has a huge appetite for work, with a bit of cheek thrown in to keep the party alive. He needs himself in mechanical form. That‘s pretty much what he‘s built.

MORE MAIN TEST READS BELOW..

In the moment

It‘s our third day-cab truck in four months so we‘re really getting the hang of this compact living thing. The Trident is another example of a wide-bodied jet in conventional truck parlance. The bonneted truck cab designers of the past must have been on a tight budget, opting for longer mirror arms over wider cabs. Although visibility is fine and the bonnet rakes away, there‘s less glass than the ProStar and more snout in view. Is that a criticism? No, probably not. It‘s hard to say. You buy a bonneted truck because you want a bonneted truck but then, because no one takes the slightest responsibility for their own actions any more, the blamegame society we‘ve created means truck drivers almost need compound eyes.

The mirrors are on big grunty single arms and traditional in shape. Again, king of bonneted truck mirrors in terms of out and out efficiency has to be the T610 Kenworth range. But the look is entirely different also, and at no stage did Magpie not know what was behind him, fail to see what was coming at an intersection, or clobber a wayward log poking out of a heap on a skid. Real safety comes back to one seat and one seat only, and if the nut in that seat is loose, all the flashing, vibrating, telematic, stability, and tracking decorations in the world won‘t matter one jot.

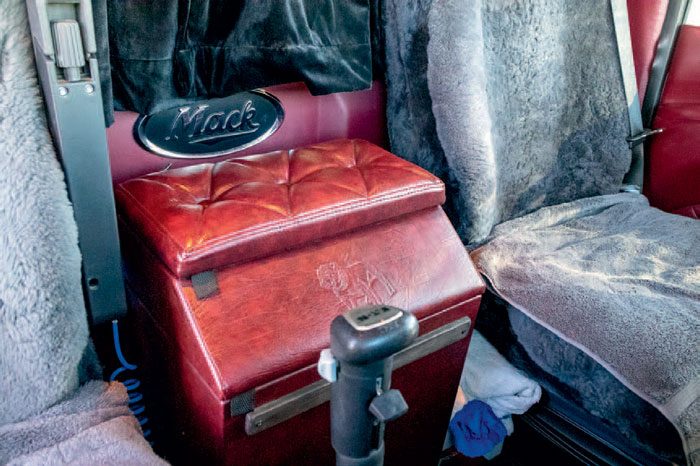

Photos: Purposeful with bucket-loads of character. Like its owner!

Inside it‘s trucking‘s tribute to the High Chaparral in burgundy pleated Ultra Leather (as the spec sheet says). There‘s a high-aspect dash with a gorgeous big wrap clad in a heavy plastic with woodgrain fascia inserts. In front of the driver are gauges galore, warning lights in the slightly downbeat ‘sad eyes‘ inserts, and in the centre top the Co-Pilot readout. The wrap houses the switchgear, trailer brake controls and valves, climate, entertainment, bush radio, and CTI controller.

There‘s no infotainment module but we suspect that‘s next year with the arrival of the Anthem. No doubt there‘ll be some gifts from overseas for family members. Almost all the switchgear is on the dash, there‘s some overhead, ‘doory‘ stuff on the doors, and headlights lower right; none of it is on the steering wheel. We‘ve found a kindred spirit on this subject, someone who likes the steering wheel for steering, and doesn‘t enjoy chasing moving buttons on windy roads. With a dash as wrapped as this, and cab as snug, there‘s no reaching for anything. Indicators and dip are on the left wand and menu selector for the Co-Pilot on the right.

Photos: Bonneted trucks always win when it comes to accessing the ‘burner‘.

Magpie‘s specced the truck with dual air seats … what a thoughtful bloke! Storage is an issue, as it is in any such machine, but the Trident came with a beautifully finished cubby between the seats, and hideaways above driver, in a central overhead console, and above the passenger. The slot above Magpie is filled with more comms radios. Aside from that, there‘s really only oddments trays and coffee cup holders under the wrap, and then it‘s outdoors to the toolboxes for the rest. Serviceability wise, it‘s a dream; there‘s nothing that ‘aint scrubbable‘ in all reality, with heavy plastics, the Ultra Leather, and rubber on the floor. Twenty minutes a day, and an hour a month, and she‘d be pretty much on-point.

Being a Volvo platform, cab safety is paramount, and so the shell is ECE29 compliant. Getting into it, on the other hand, is challenging, and even though it‘s a conventional, grab handles on the lower A pillar would be a boon. Accessing the heart of the matter is outrageously easy of course. Drop the bull-bar, flip up the nose and there‘s the MP8 smiling back at you with no real accessibility issues, even with the back pot tucked into the firewall.

Photo: The interface between the mechanical components and the CPU of the world‘s most intuitive transmission.

Photo: The interface between the mechanical components and the CPU of the world‘s most intuitive transmission.

Time traveller in the trees

In many ways, Mark Amer‘s a living embodiment of what trucking was like a generation or two ago; before the invention of hollow authority, hard to explain positions, and weird infrastructure. When skilled practitioners, taught at the hands of their parents, moved a tonne of crap around the nation on a premise ingrained into them that work will set you free. That good things came to those who worked for them, not through applying for a higher credit limit. That If we build a great country, we‘ll get better roads and facilities. [‘Can we get those people back? …No? Okay.‘] He‘s like that not just because of the grounding dad Kelvin and mum Marie gave him, but because he‘s seen the realities of how close it can all come to ending. He‘s seen tough times since swapping window envelopes with a wage slip in them for ones with invoices. Huge repair bills that made the hair on the back of his neck stand up.

“The problem with a lot of people is they just give up too easy. Shit, I‘ve had times when I had no idea if I was going to be able to keep going – but you just get in and do the next load, and the next, and the next. Don‘t give up. Do whatever it takes to keep going. “I put the chrome wheels on the trailer and social media lights up about owner-drivers and having too much money. Come have a go is all I say.”

Photo: A man and his machine.

Born and raised in Christchurch, 45-year-old Mark was the fourth of four born into trucking. Eldest brother Glenn runs trucks in Christchurch. David (Spike) has driven trucks all his life, and sister Karen married a trucker and has a son who‘s followed his father into the industry. There‘s no doubt the Amers have done their bit to stem the driver shortage. Grandfather Les Whittle was a local businessmen and trucking was part of his portfolio. “He built the first articulated horse float in the country, having seen one in the States.” When Mark came along, his father Kelvin was driving for Habgoods Transport, a large Canterbury transport company of the time. He then went owner-driver and spent many years with the likes of Alltrans Express, TNT Alltrans, and Falcon Forwarders, before finishing with Ivory‘s Freight running an R Model Mack and container side-loader – a truck Mark drove for him for a spell. Kelvin is 76 now and is just in the throes of having another go at retiring. So, there‘s a snapshot of the example set.

School and Mark weren‘t the closest of associates. The education system couldn‘t deliver the learning he was after; – the local truck yards could, so it was an exit from Hillmorton High School at the earliest available juncture. “I left before I was kicked out.” His first foray into the industry had been working after school and during holidays in the parts department of trailer builder Steel Brothers NZ Ltd, and his first real driving job was with Tranter Trucking on a Ford Trader, working up from there to semi-trailer combinations “like you had to then!” Then came Stock Transporters Ltd. “It was the best apprenticeship any young fella could ever have. Everyone should have to do six months with Shane at STL. The camaraderie is great, and the learning! I‘m still mates with Shane today and we frequently have a beer on a Friday night. That‘s the kind of outfit it is,” Mark says. With that experience under his belt and confidence in his abilities, the industry opened up and he did spells in Nelson for R&B Freighting, at Westport for Johnson Brothers Transport, for his dad on the R-Model at home, and then Container Transport and Storage in Christchurch.

He then got a shot at the fuel distribution business through Mobil Oil contractor Dave Chambers and grabbed it with both hands. He left shortly after the Allied takeover, securing a role with Alexander Petroleum Ltd. “I would still rate that as one of the best jobs I‘ve ever had, and for company owned trucks they certainly had the best gear anywhere.” While working at Alexanders and keeping the Freightliner Argosy he drove as polished and pristine as is humanly possible, a workmate made the observation that Mark was ‘like a bloody Magpie‘. Fleeting moments in time that impact your life forever. Following a change in the work a couple of years in, he went and drove a drop-sider for East Coast Bays Holdings before beginning his true date with destiny at Steve Murphy Ltd. “Steve gave me three months to learn to drive a loader. ‘If you can‘t load yourself in the mornings, you‘re no good to me,‘ he warned.”

Photo: Mark Amer. Put on the world to cart stuff!

Photo: Mark Amer. Put on the world to cart stuff!

Although the job was great and the company fantastic, Mark wanted to see his name on the door of his own truck. He made overtures from time to time about potential opportunities, but owner-drivers weren‘t something traditionally part of the SML plan – so he thought he‘d have look elsewhere. When the chance of a contract with Waste Management came up, he thought that might be his ‘in‘ to the world of truck ownership. As it turned out the jousting and banter between two stubborn characters had built a mutual respect and Steve Murphy decided to give a good keen man a crack. He sold him one of the company‘s trucks, a K model Kenworth with

Read more

Of culture and longevity

0 Comments37 Minutes

Life’s essentials

0 Comments43 Minutes

Hiding in plain sight

0 Comments34 Minutes