FONTERRA‘S JOURNEY FROM EXPLODING BATTERIES TO INCREASING FLEET EFFICIENCY

A three-way partnership aimed at improving battery reliability across Fonterra‘s milk tanker fleet has had health and safety benefits as well as boosting the co-op‘s bottom line.

A decade ago, when Guy Cooper took up the role of national parts and warranty manager at Fonterra, one of his priorities was tackling a worrying problem with truck batteries in the dairy co-operative‘s milk tanker fleet. For a start, battery life was alarmingly short. In the 2010- 11 financial year the fleet of 432 trucks chewed through 1422 batteries with some having to be replaced after less than three months. But more concerning for Guy was that a relatively high number of batteries were exploding, posing an obvious safety hazard to drivers and mechanics, as well as compromising efficient operations. “These battery explosions generally happened during jump-starting attempts,” he explains. “While our staff are always wearing PPE in these situations, we clearly didn‘t want to put anyone at risk with acid and chunks of battery material flying around. It was imperative, from a safety point of view, to address the problem.

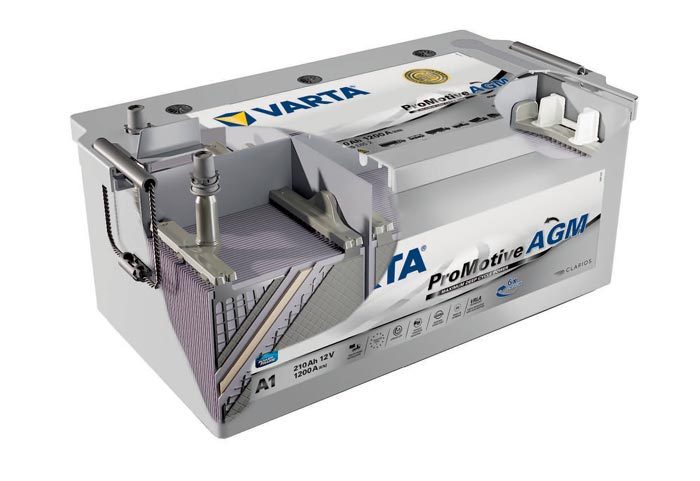

“At the same time, with battery life sometimes less than three months, we saw this as an area where we needed to improve reliability, which would result in cost reductions. Back then, in 2010, we set a target of getting to two years life out of a battery.” Ten years on, Fonterra is well on its way to achieving that goal, thanks to a strong and enduring relationship with its battery supplier, HCB Technologies Ltd, and a history of success with their chosen brand, VARTA®. Thanks to that relationship, Fonterra – and its drivers – are already enjoying the benefits of VARTA®‘s latest and most advanced heavy duty commercial vehicle battery, the ProMotive AGM, introduced in September 2019. Having been on the market for over a year now, the ProMotive AGM has performed strongly for Fonterra, mirroring a success story that has already been seen in the EMEA region.

A hard-working tanker fleet

In his role as national parts and warranty manager, Guy reports to Fonterra‘s general manager of national transport, whose division is accountable for the provision of the New Zealand-wide milk collection fleet, currently comprising more than 500 truck and trailer units. With the tankers operational 24 hours a day, it‘s one of the hardest working fleets in the world. At peak times, the trucks will make a total of about 3000 journeys a day, collecting milk from almost 9500 farms. Each vehicle travels about 200,000km over the course of a year, meaning the entire fleet clocks up around 95 million km on the road annually. Those impressive numbers, and the fact that milk collection can‘t be interrupted, mean that reliability is one of the key tenets around maintaining the fleet, Guy says. The trucks are equipped with a sophisticated Electronics which control everything from Driver and Engine management, the pickup schedule and mapping through to the onboard sampling and measuring the milk collected at each site. Because of the importance of these systems, Fonterra can‘t simply go out and hire a replacement vehicle if one of its fleet is unexpectedly off the road.

“When we know there‘s an issue going on with the fleet, we don‘t just fix our trucks, we‘ll do in-depth analysis to define the problem and then we‘ll carry out a problem solving exercise aimed at improving reliability. We‘ll then feed our findings back to the manufacturer of the truck or the component concerned,” Guy says. “We work very closely with our suppliers and OEMs (original equipment manufacturers). Over the years we have affected quite a few engineering changes that have been introduced globally. “We find that because of our high usage and the uniqueness of how our fleet operates – for example our trucks are running empty about 55 percent of the time, and often on gravel roads, which means they work under some tough conditions – we usually find problems quite early on in a model‘s life. We feed that back to the manufacturers, and because we can supply good data to demonstrate the root cause, they‘ve got the evidence to make changes.”

Demands on truck batteries grows

Around the world, heavy commercial fleet operators are finding the demands on batteries in their vehicles have increased significantly as the amount of onboard electronic equipment continues to grow. “With our trucks spending a large portion of their time on unsealed roads, and empty, when there‘s no weight to steady up the suspension, that leads to quite a bit of movement. Sharp shocks in the trucks under these conditions have been measured at up to 9G in the battery box, so the batteries certainly take a hammering,” Guy says. “Another safety aspect is that these batteries are heavy – up to almost 60kg each – so you don‘t want technicians on the roadside changing them, it‘s too much for them to lift. We‘re at the point now where if there‘s a failure, the batteries should be able to recover back to site where we can use mechanical handling equipment to make the change so there‘s no lifting involved.”

Fonterra‘s relationship with HCB

Fonterra‘s relationship with HCB dates back to 2010 when it asked HCB to participate in a request for proposal process (RFP) for the supply of batteries for the co-op‘s tanker fleet. HCB has been New Zealand‘s battery specialist for 30 years, offering the widest range and the biggest depth of product, and the most knowledgeable people in the industry. HCB is part of the Bapcor group of companies. Bapcor is the sole distributor for VARTA® batteries in Australasia. As part of the 2010 RFP process, HCB carried out field testing – included monitoring open circuit voltage, current draw and vibration tests – to assess the performance of the batteries Fonterra was using at the time. Two sets of batteries that had failed after three and nine months respective usage were torndown and analysed. HCB then prepared a report on the findings of its testing and analysis, along with a recommendation to switch the fleet to an alternative battery type. The work resulted in HCB picking up the contract a few months later and following up its initial testing with an 18-month trial to monitor the performance of the new batteries, which showed an impressive success rate of 99.6 percent.

At the same time, HCB worked with Fonterra to carry out site audits of battery handling and charging equipment, developed standard operating procedures, and carried out onsite training with Fonterra staff on safe testing, correct battery handling, preventative care and general battery maintenance. This resulted in a drop in battery-related safety incidents across the co-op and led to HCB winning the ‘Best Safety Initiative Which Enhances Health and Safety Performance at Fonterra‘ award at Fonterra‘s 2013 Vendor Awards. “Early on in our relationship with HCB we also purchased new chargers and modified all our trucks to be fitted with Anderson plugs, the large high-amp charging plugs that fit directly into the side of a vehicle, eliminating the need to lift the battery cover,” says Guy. “We received excellent support from HCB as we set up these changes. That type of support has certainly been one of the benefits we‘ve enjoyed through our relationship with them.”

VARTA® delivers performance boost

With the problem of exploding batteries well in the past by 2015, a desire to continue making performance and reliability improvements saw Fonterra and HCB begin work on transitioning the fleet to VARTA® batteries for the first time. The VARTA® brand has a strong global reputation for its heavy commercial vehicle batteries and Fonterra initially installed VARTA®‘s ProMotive Super Heavy Duty (N9) model across its fleet before moving to the even higher-performing ProMotive EFB (C40) in 2017. The move to VARTA® resulted in Fonterra‘s average battery life increasing significantly to around 16-18 months following the introduction of the ProMotive EFB which, like other batteries before it, was trialled in a small number of tankers before its wider deployment across the fleet.

Clarios, the owner and manufacturer of VARTA® branded products, has worked closely with Fonterra and HCB as part of the trials, including making visits to Fonterra sites and organising tear-down analysis of the batteries being trialled. Clarios are also suppliers to Volvo, the manufacturer of the majority of Fonterra‘s tankers, which are made in Brisbane. “We catch up with the Clarios reps once or twice a year. Recently it‘s been important to have that connection to support Volvo Group Australia to ensure they can supply the battery we want into the trucks that are being built for us in Brisbane,” Guy says. “Through our Clarios contacts we‘re connecting with Volvo to ensure they have sufficient batteries for the trucks that are coming to New Zealand.”

Latest technology set to deliver further improvements

In 2019 the next phase of Fonterra‘s journey towards achieving its two-year battery life target got underway when it became the first customer in Australasia – and one of the first in the world – to trial VARTA®‘s new top-of-the-line heavy commercial vehicle battery, the ProMotive AGM (A1). The ProMotive AGM is designed to optimally support drivers and their trucks during their time on the road. Since the demand for nonstop transportation services require trucks to be on the road every day, drivers spend more time in the cabin than ever before, increasing the demand on their vehicles‘ batteries. The AGM meets this challenge, offering excellent charge acceptance, extended cycle life and increased depth of discharge. It also has exceptionally high vibration resistance, making it ideally suited for New Zealand roads where the problem of reduced battery life due to vibration has plagued truck and fleet owners. The ProMotive AGM was initially trialled in three of Fonterra‘s tankers. One of the three battery pairs was removed and torn down after six months. It was found to be performing on par with a brand-new battery, with no degradation.

A second pair was pulled out and torn down in August 2020 after the truck had travelled 280,000km. While it was showing some signs of wear and tear, Guy says the degradation was less than expected after that much usage. The co-op has subsequently fitted 17 more ProMotive AGM pairs across its fleet and is expanding that number further as batteries need replacing. “The longest running ProMotive AGM – the third of the original three we installed – has now done over 300,000km after about 18 months. It‘s going well, with no signs of failure, so we‘re highly confident we‘ll reach our two-year target with this new model of battery,” he says. “With our next lot of Volvo trucks that are being delivered in 2021, we‘ve specified that they will come fitted with the ProMotive AGM straight out of the factory.” The AGM has already been adopted by many commercial fleets in the EMEA region, proving that it is the first choice with both OE and aftermarket customers. OE manufacturers, such as Volvo, MAN and DAF, have transitioned to AGM in their portfolios because it is especially designed to fit the needs of today‘s trucks.

A tried-and-true formula for success

“As well as a focus on safety, within Fonterra‘s National Transport division our aspiration over many years has been to have the most cost-effective and efficient fleet in the country, and we‘re well on the way to achieving that,” Guy says. “In terms of the evolution of batteries, we haven‘t got here by accident. We‘ve always had formal trials, we‘ve defined up-front what success looks like, and then at various stages – whether it‘s three or six months – we‘ve taken a set of batteries out and HCB have torn them down and done an in-depth inspection to see what condition they‘re in. “We measure all aspects of our fleet operations, right down to the individual truck level, so we know which truck is more cost-effective than the others, even though we‘ve got a fleet of over 500. “Having that data available makes my job much easier, as does having great vendors like HCB, who listen and understand what we‘re aiming to achieve. Rather than being in my face, just trying to sell me new products all the time, I feed back to them what‘s going on and they use that information to come up with a solution for us. “The end result is that while we‘re now paying more per unit for our batteries than previously, we‘re getting significantly improved life, so we‘re spending less overall.”

The benefits of an honest relationship

Guy says Fonterra‘s relationship with HCB – in line with the way the co-op likes to operate – is about feedback and having an honest communication. “We could be involved with someone whose sole motive was to sell as many batteries as possible. It‘s been more a case of us needing a battery technology that‘s reliable, and gives us the best value option. Our requirements are firstly safety, then reliability and value to the business. “The success of our relationship with HCB is demonstrated by the fact we‘ve moved from consuming more than 1400 batteries in a season for a smaller fleet to 300 – it‘s a huge change over the time. And while those earlier batteries were cheaper, it meant people had to lift a 50kg battery, so it‘s about the human interaction as well. Having drivers who don‘t have to touch a battery box for two years is a big achievement, as opposed to every three or six months. He says the relationship has evolved over the past 10 years. “It‘s been great working with them to define where we‘re going, and they‘ve taken that onboard. “Individuals come and go, as with any organisation, but the main tenant has remained: that they understand what Fonterra‘s requirements are, and have always provided the technical ability and the sales ability to meet those demands. “This is particularly in relation to the fact the VARTA® product comes from overseas, so getting the right amount of supply into the country can be a challenge, and that‘s where HCB come into their own because they work very hard in that space, and if a particular battery is not available they‘ll readily make a suitable alternative available.”

About Fonterra

• A global brand, processing about 83% of New Zealand‘s milk

• Generate about $11b into the NZ economy through the milk price

• At peak production, collect about 85 million litres of milk per day, or 16 billion litres a year

• 30 manufacturing sites across New Zealand

• Run a fleet of more than 500 truck and trailer units, operating 24/7