One electrical system with two voltages is not uncommon. To make it all work the vehicle needs a series-parallel switch between them. But the truck will go nowhere if the switch can‘t, well, switch.

Photo: The basic schematic layout of a 12/24V series-parallel switch.

I recently took an old W Model Kenworth for a short run. The old girl hadn‘t been started for ages and, needless to say, it needed a little coaxing into life. With the master switch turned, my joy and excitement quickly disappeared when I turned the key and there was the click-click sound of a flat battery as the starter tried to wind over the old 400hp CAT under the hood. I sat for a few moments leaning on the steering wheel looking out over the bonnet, and a few old memories came flooding back of the days when I drove one like this. One memory in particular stuck in my mind… I‘d volunteered to do a run north for a mate. A few days later, late at night in a parking bay between Mount Isa and Camooweal, I slid into the seat, turned the key and hit the starter. Nothing! I hit it again. Still nothing. Even today, auto-electricians are fairly scarce around midnight and mobile phones are not conducive to communicating your needs in this particular area. I remember thinking that night, ‘if I‘m going to get back on the road tonight there‘s no alternative other than to get out into the two-inch-deep dust and fix the problem myself ‘. After all, it‘s what most blokes did in the bush back then.

Photo: A typical switch installation.

The yellow Caterpillar sprang to life about half an hour later. The reason the truck wouldn‘t start was because the solenoid in the series-parallel switch had jammed. The fine tolerances inside the solenoid show little forgiveness for the entry of foreign particles, especially dust, and there‘s plenty of that out here in Australia. This type of switch is not found on many modern trucks. European vehicles run 24V systems so don‘t require it, and most US machines now have 12V starters. While becoming a rarity, there are still many older models on the road that have them and some customers specifically specify them because they prefer the rapid cranking of a 24V starter. Understanding how they work may just help to get you mobile again should you ever happen to experience a similar situation. The best description of a seriesparallel switch is that it is a mechanism that allows for two 12V batteries to be linked in series (forming 24V) for starting, while also linked in parallel (12V) for charging. When batteries are connected via the positive on one battery and the negative on the next battery, the value of the two batteries is added together. Therefore, two 12V batteries connected in series equal 24V of output. When the positive terminal of one battery is connected to the positive terminal of another battery with the same applying to the negative terminals, it is connected in parallel. This basically means that if you have two 13-plate 12V batteries you effectively have one 26-plate 12V battery when they are connected in this fashion.

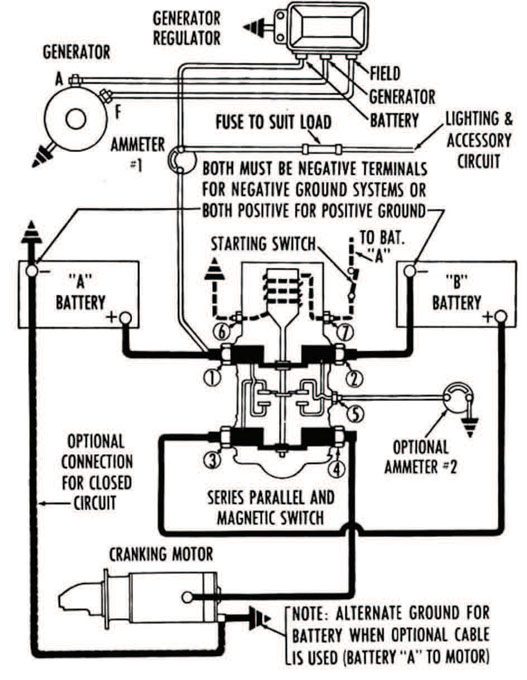

Photo: Circuit diagram of a typical seriesparallel switch completing a series connection between batteries for 24V starter motor operation.

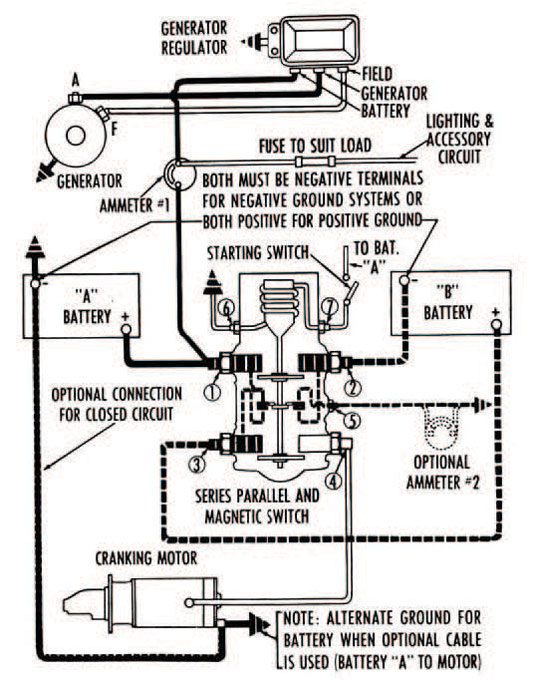

Photo: Circuit diagram of a typical series-parallel switch completing a parallel connection between batteries for normal operation of vehicle electrical equipment at 12V.

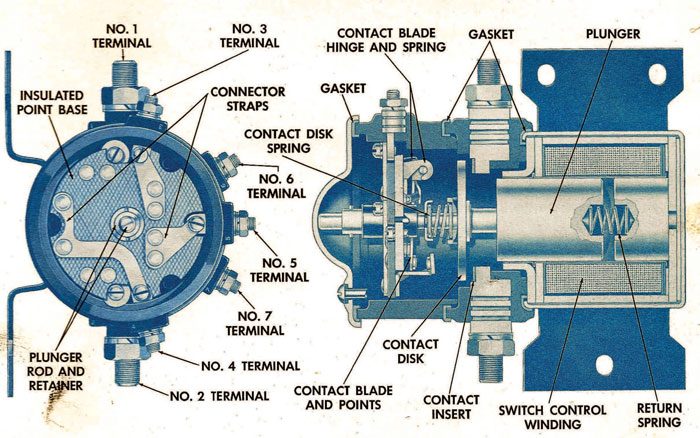

To obtain 24V and connect the batteries to the starter motor a seriesparallel switch is used. So, this old girl had a 24V starter motor to get the Cat cranking into life, and the rest of the truck‘s electronics ran on 12V. A series-parallel switch consists of four sets of contacts that we‘ll call, 1, 2, 3 and 4. Contacts 1 and 3 and contacts 2 and 4 are connected, as they are spring loaded. When the starter key is activated the series-parallel solenoid coil is energised and the plunger moves, disconnecting contact 1 from 3 and contact 2 from 4. This connects the two batteries in series with the starter motor. At the same time, the starter motor solenoid circuit is closed by the second set of contacts 3 and 4, and the starter motor rotates. When the key is released, the batteries return to a parallel connection as the series-parallel switch contacts 1 and 2 are opened and contacts 1 and 3 and 2 and 4 are reconnected. The two batteries are charged in parallel by a 12V alternator and supply the accessories at 12V. So, how did I get the jammed solenoid free? First, I had to determine the cause behind the truck‘s inability to start, as it was fine until the attempt to leave the parking bay. Thorough checks of the batteries, ensuring all leads were firmly fastened to the terminals, and a check of the starter motor, ensuring its connections were secure, were the first steps. There was plenty of power as the lights shone brightly on all three trailers. The next check was for broken wires that may have caused a short.

The series-parallel switch was quite warm and made a clunking sound similar to a car with a flat battery. It sounded as though it was trying to work, suggesting that the starting problem was connected to the switch. Once determining that it was a jammed solenoid, I proceeded to give the switch a few swift blows with a ball-peen hammer. I doubt that you‘ll find this procedure recommended in any workshop or manufacturer‘s instruction manuals. On the side of the road in the middle of the night, however, this bush methodology will more often than not get you on your way again as it frees the dust that accumulates inside the switch. The offending switch was removed upon arrival at our destination and serviced by a fully qualified auto electrician, who confirmed that dust had indeed caused the problem.

Read more

Wide load follows

0 Comments9 Minutes